Digital supply chains have been a global trending topic for a few years now, even more so with the rise of multiple technologies. The chemicals industry is fully aware of this and thus made digital transformation the main subject of the LogiChem 2018. Supply chain directors of the leading chemical manufacturers shared their approaches to leveraging technology in order to face the industry’s current challenges in Amsterdam.

Realistic Transformations

When starting to walk the road of becoming more agile and replacing tools like Excel with specialized software for the management of diverse processes, organization can get “lost in transition”. Carsten Weers, Head of Global Supply Chain Management at BASF, thus explained the company’s strategy to initiate and drive realistic transformation overcoming the lack of implementation capability.

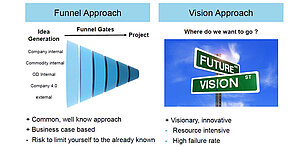

Using a funnel approach, they started out using a wide range of internal and external sources to identify digitalization opportunities. Then they prioritized a few projects with high impact on the business, fast implementation time and rollout potential. Finally these projects were implemented, scaled and aligned between business units. Weers named 4 key success factors of digital transformation projects: focus on fixing urgent pain points of the business, generation of immediate success stories, sharing of best practices and small initial steps with subsequent fast scaling.

Source: Carsten Weers, Head of Global Supply Chain Management, Monomers Division BASF. Logichem 2018 keynote.

Balancing transformation and operations

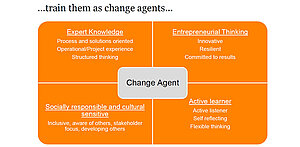

The industry landscape shows big technology and consulting players investing billions to accelerate the digital transformation of global manufacturing as well as wide spread discussions about big data, blockchain, and artificial intelligence. In this context, Sibylle Mutschler, Head of Digital at Clariant, drew attention to the fact that the executive management board’s commitment is a must in order to succeed in one’s digitalization endeavors.

Outlining the digital path is absolutely necessary, but Mutschler warned about the risk of coming into an “over planning mode” when trying to drive operational efficiency using digitalization. Project kickoffs are decisive steps that need to be taken while the everyday business processes still have to work. Mutschler thus reminded: “You have to run and you have to do your plan and projects while running”.

Source: Sibylle Mutschler, Head of Digital, Clariant. Logichem 2018 keynote.

Chemicals industry calls upon a shared platform

Customer expectations are getting higher as retail companies like Amazon are able to deliver orders quickly and with full visibility. Consumers are getting used to fast and simple transactions and that raises the bar for the B2B markets as well. Therefore, the need for creating a common platform which enables chemical companies to collaborate was also addressed at the LogiChem 2018.

At the biggest supply chain event of the industry it was clear that the Chemicals sector is convinced of the importance of digitalization to deal with supply chain key inefficiencies like manual processes and lack of transparency. They can be tackled embracing the digital transformation journey and a TMS is one of the best tools that can help industries to do it.